5 Axis CNC Machines

HURON

HURON’s machine tool design integrates both standardized and bespoke machinery concepts. Our planning process is intricately tailored to meet each customer’s unique machining requirements. Commencing with a selection from our range of basic machines initiates the planning phase. Subsequently, a plethora of customizable options supplements the machine, culminating in an optimal production solution. HURON’s innovative Modular Component System, characterized by its ingenuity, facilitates the accommodation of nearly all customer demands in metal cutting.

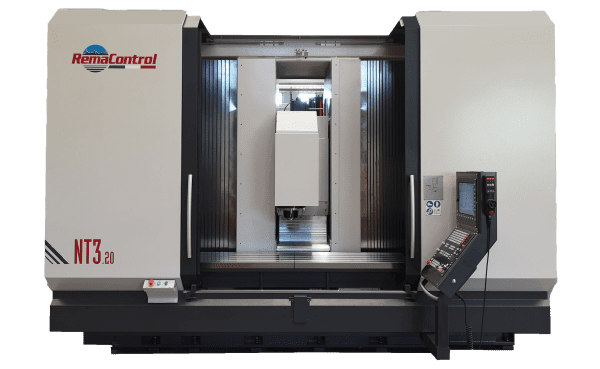

Rema Control - NEWTON

NEWTON is the smallest model of Rema Control’s family of vertical machining centres with moving gantry. The base is monoblock and well-sized, electrowelded and stabilised following the latest thermal treatment technologies which ensure high stability, rigidity and sturdiness.

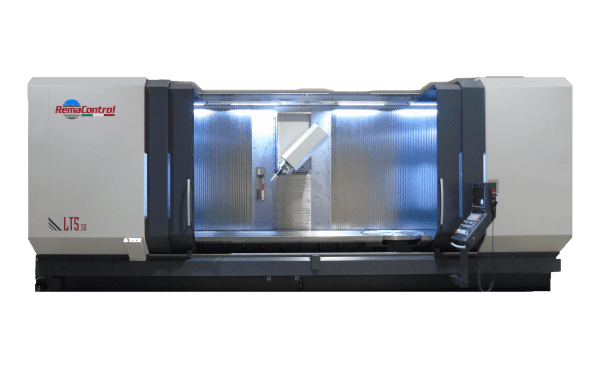

Rema Control - Leanord

LEONARD is the first born of the family of Rema Control’s vertical machining centres with moving gantry. Highly reliable machine thanks to its top quality components and to a smart design that minimises maintenance requirements. Besides its high rigidity and precision, LEONARD features great machining flexibility and ease of tooling and piece clamping.

Rema Control - RAFFAELLO

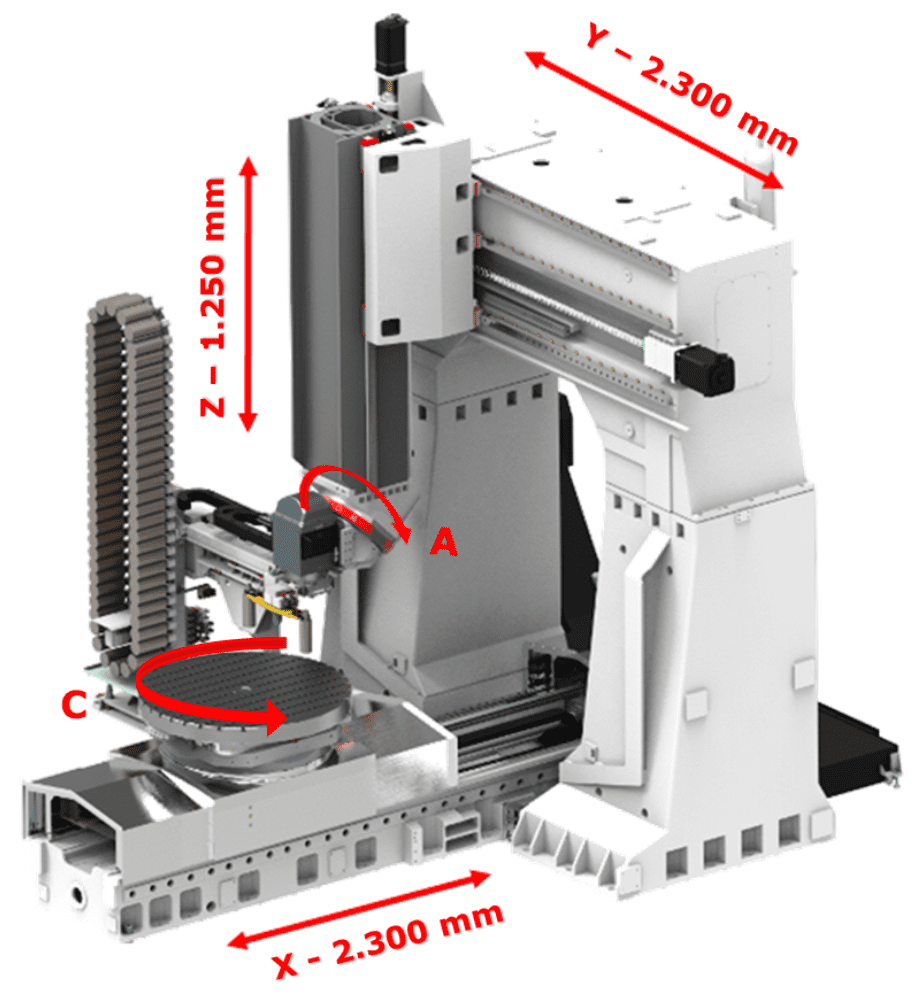

RAFFAELLO is the 5-axis vertical machining centre with tilt rotary table born from the years of experience of Rema Control in 5 simultaneous axes applications and built to meet the highest machining requirements in terms of reliability, speed and precision. The family of RAFFAELLO machines includes 4 versions of growing dimensions (from 400 mm to 1400 mm of X-axis travel) and 2 further special models with an ISO 50 configuration. All the models are then further customisable through several available options (e.g. spindle with specific characteristics, expandable tool magazine and various measuring and cooling systems) so as to make a tailor-made product that meets each customer’ specific needs.

What Are 5-Axis CNC Machines?

5-axis CNC machines stand as cutting-edge technological marvels within the realm of machining. Unlike their conventional counterparts limited to three axes (X, Y, and Z), these advanced tools operate on an additional two axes — A and B or C — unlocking a realm of precision and complexity previously unattainable.

The dynamic motion of 5-axis CNC machines allows for the meticulous machining of intricate designs and complex details with minimal setup requirements. This innovation marks a significant advancement in CNC machining, catering to the evolving demands of industries such as automotive, aerospace, and manufacturing.

Integrating a 5-axis CNC machine into your production line is pivotal for enhancing production capabilities with:

- Enhanced surface finish and superior product quality.

- Ability to fabricate intricate parts in a single setup, streamlining production processes.

- Reduced preparation time facilitated by advanced CNC controls.

- Substantial improvements in tool life, accompanied by minimized tool wear.

Embracing 5-axis CNC technology opens doors to unprecedented levels of precision and efficiency, revolutionizing manufacturing processes across diverse sectors.

5-axis CNC machines are technologically advanced cutting machine tools designed to make precise, intricate, and complex cuts that can’t be achieved using conventional CNC machines. Unlike traditional CNC machines which operate on three axes (X, Y, and Z), 5-axis CNC machines operate on an additional two axes — A and B or C — allowing for much more versatile and precise machining.

The dynamic 5-axis motion these machines present, permits precise cutting of complex designs and intricate details with minimal set-ups. These machines represent a revolutionary leap in the realm of CNC machining, with their user experience tailored to meet the ever-evolving requirements of the industries they serve, be it automotive, aerospace, or manufacturing.

The implementation of a 5-axis CNC machine to your production line is key to enhancing production capabilities. These machines offer the following benefits:

- Improved surface finish and quality of the finished product.

- Capability to execute complicated parts in a single setup.

- Minimized preparation time due to advanced CNC controls.

- Highly improved tool life and significantly less tool wear.

Implementing a 5-Axis CNC Machine in Your Production Line

Effective implementation of a 5-axis CNC machine demands meticulous planning. Integrating this cutting-edge technology into your production line offers a plethora of benefits, including heightened accuracy, enhanced productivity, and streamlined processes. To maximize these advantages, careful consideration and preparation are essential.

First and foremost, comprehending the workings of these machines, along with their capabilities and limitations, is paramount. Gaining technical insight into aspects such as automatic tool changing mechanisms and mill tool holding intricacies are invaluable. United Precision Services offers comprehensive training and ongoing support to ensure optimal utilization of your 5-axis CNC investment. Our experts provide guidance on maintenance protocols, operational procedures, and troubleshooting techniques, fostering operational proficiency.

Assessing spatial requirements and determining the optimal location for your CNC machine are critical steps. Whether it’s a vertical mill, universal mill, or horizontal lathe, sufficient space is needed for safe and efficient operation. Therefore, evaluating your production floor’s layout, confirming electrical cabinet needs, and creating a conducive environment devoid of excessive heat are vital considerations.

Upon successful integration, your production line stands to experience a significant surge in productivity and precision. 5-axis machining centers empower manufacturers to deliver intricate parts with unparalleled accuracy, setting new standards in manufacturing excellence.

Key Features of Our 5-Axis CNC Machine

In the realm of manufacturing, possessing cutting-edge, dependable, and exceptionally efficient machining equipment is pivotal for success and growth. Our 5-axis CNC machine stands at the forefront, providing a distinctive array of features that enable you to surpass competitors. With unparalleled precision, time-saving production capabilities, and exceptional durability, our 5-axis machining center is poised to surpass expectations on every production line.

Unmatched Precision and Accuracy

An outstanding attribute of our 5-axis CNC machine is its unmatched precision. Equipped with advanced features like precision cutting tools and an automatic pallet changer, our machine facilitates the creation of intricate workpieces and complex design configurations with exceptional accuracy. The user experience is elevated through innovative design and functionality.

Toolholding play a crucial role in achieving precision and efficiency during milling operations. By securely holding and stabilizing cutting tools, they minimize tool chatter and deflection, thus ensuring the quality of machined parts. This enhances the overall precision and productivity of the milling process. Furthermore, our kits enable swift and automated tool changes, allowing manufacturers to adapt to different materials and cutting operations seamlessly, thereby increasing machine flexibility and productivity.

Integrated Software Solutions

Our 5-axis CNC machines boast cutting-edge integrated software that transcends conventional boundaries, seamlessly connecting CNC controls with contemporary applications. This intelligent automation not only enhances the user experience but also provides superior control over programming and part production workflows.

Moreover, our machines feature advanced automation through machine tool analytics monitoring. This sophisticated system offers insightful data on equipment effectiveness, utilizing self-diagnostic capabilities to track machine utilization metrics. This enables identification of areas for productivity enhancement and prediction of maintenance requirements. Additionally, remote connectivity facilitates troubleshooting assistance and enables over-the-air software updates, ensuring optimal performance.

By streamlining setups, changeovers, and recurring operations through automation, our technology reduces the need for manual machine management, allowing staff to focus more on value-added tasks such as part handling and quality control checks. Our comprehensive approach, combining user-friendly controls with integrated analytics, offers holistic solutions to maximize the efficiency of your equipment.

Minimizes Production Time

An overarching benefit of our 5-axis CNC machine lies in its capacity to significantly streamline production timelines by consolidating multiple machining operations into a single setup. The simultaneous 5-axis configuration enables the machining of intricate, curved 3D contours in a single swift cycle, eliminating the need to re-fixture parts across multiple standard 3-axis machines. This eradicates additional alignments, changeovers, and transitions between processes, resulting in a reduction in both total cycle count and lead time required to complete finished components.

Moreover, the reduction in changeovers and handling diminishes the likelihood of human error or accidental damage during transfers. This decrease in potential scrap or rework not only saves time, materials, and tools but also contributes to maintaining an accelerated schedule. Our 5-axis machining centers epitomize intelligent design tailored for high-mix workflows, where rapid changeovers are essential for meeting tight delivery deadlines.

High Durability and Versatile Capabilities

Designed and manufactured for durability and versatility, our robust 5-axis CNC machines are engineered to tackle a wide array of applications with ease. Featuring a rugged construction and precise motion control, they excel in machining large, intricate components with finesse. The solid frames provide a stable platform, capable of withstanding rigorous cuts and extreme pressures encountered in demanding continuous production environments.

Our machines boast advanced locational capabilities, enhancing maneuverability in navigating tight contours and complex angles effortlessly. Equipped with decoupled drives, they deliver unparalleled torque, facilitating the manipulation of bulky parts with precision. The flexibility of CNC machining allows for seamless adaptation of existing programs to accommodate parts with varying configurations or requirements.

With reinforced structures and robust capabilities tailored for heavy cutting, our 5-axis solutions are built to endure, ensuring long-lasting value and relentless performance to meet the demands of round-the-clock operations.

FAQs

What are the main benefits of a 5-axis CNC machine?

The principal advantages of a 5-axis CNC machine include completing complex parts in a single setup with no need for refixturing, improved precision and accuracy, shorter cycle times, superior surface finish quality, more uptime, and greater all-around part quality.

What types of parts are ideal for 5-axis CNC machining?

5-axis machining excels at producing intricately shaped components calling for undercuts, complex curves, and contours like turbines, impellers, molds, prototype parts, aerospace components, and automotive pieces.

What industries typically use 5-axis CNC machines?

Aerospace, medical, automotive, mold and die shops, and energy industries like wind power rely heavily on 5-axis. But an array of machine shops and other metal fabricators making large, complex parts may find these flexible CNC solutions highly valuable for taking business to the next level as well.

* Indicates required entries.